Topson Group Provides Quality Stainless Steel Decorative Sheets Gobally.

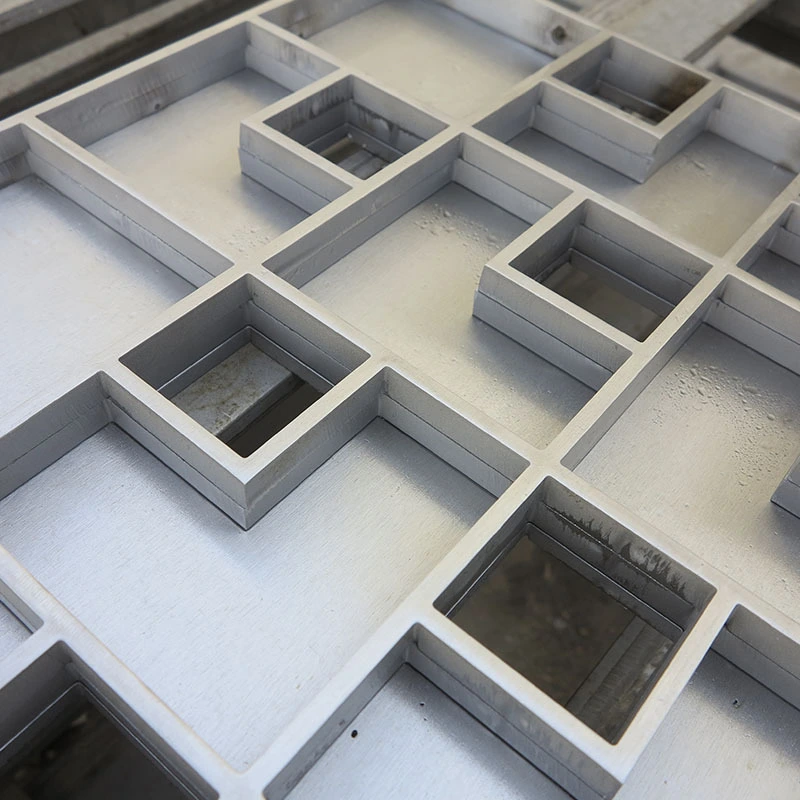

Stainless steel Tray & stainless steel inspection covers

Technical Specifications

| Product | Stainless steel removable tray & access cover |

| Material | Stainless Steel Sheet ,Steel Plate |

| Fixing | Floor mounted on the ground |

| Processing | Cutting, Bending, Welding, Polishing, Coloring |

| Customized design | Pattern according to your sample or CAD drawing |

| Product Code | Clear Opening | Tray Depth | Visible Frame Size |

| TSP-450/450 | 450mm x 450mm | 80mm | 552mm x 552mm |

| TSP -600/450 | 600mm x 450mm | 80mm | 702mm x 702mm |

| TSP -600/600 | 600mm x 600mm | 80mm | 702mm x 702mm |

| TSP -750/600 | 750mm x 600mm | 80mm | 852mm x 702mm |

| TSP -750/750 | 750mm x 750mm | 80mm | 852mm x 852mm |

| TSP -900/600 | 900mm x 600mm | 80mm | 1002mm x 702mm |

| TSP -900/750 | 900mm x 750mm | 80mm | 1002mm x 852mm |

| TSP -900/900 | 900mm x 900mm | 80mm | 1002mm x 1002mm |

* Customized sizes to suit exact paving slab dimensions available in small production runs at no extra cost.

Description

Topson Solo Paver Tray& Access cover for Block Paved Areas, have unique Laser Cut lettering on the lifting corners to indicate services.

The recessed cover units are manufactured in accordance with EN124 and FACTA stanadards and are available in various loadings. The covers are 80mm/100mm deep as standard and are fabricated in 3mm, 4mm, 6mm, 8mm 10mm or 12mm thick stainless steel as standard, and galvanised versions are available.

Processing

1.

Cutting: This involves various tools or machines removing excess material from a workpiece to meet size and shape requirements. Band saws and cutting torches are two examples of cutting devices.

2.

Forming: This process uses deforming equipment, such as hydraulic brakes, to bend or press products at a specified angle.

3.

Machining: Machining processes, which include lathing, milling, drilling and honing, use automated or manually controlled equipped to shape material.

4.

Welding: Welding is the process of joining two or more workpieces by applying heat or pressure to form a single product.Customized design

5.

Pattern according to your sample or CAD drawing.

Features

Type

Metal works and stainless steel products are everywhere.

CONTACT US

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China