Topson Group Provides Quality Stainless Steel Decorative Sheets Gobally.

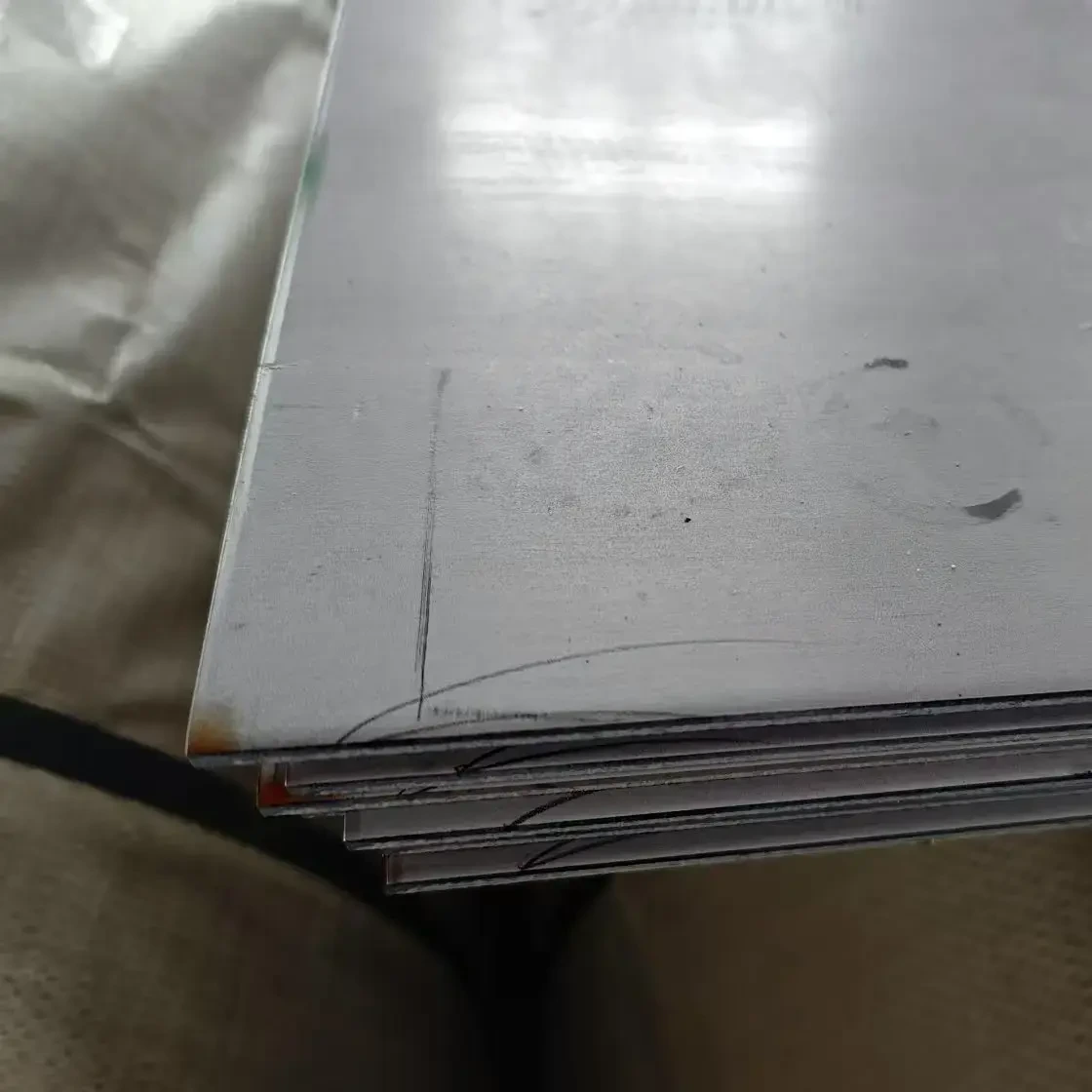

No.1 Finish Stainless Steel

The surface of hot-rolled stainless steel comes in 5 grades. No.1 is the primary surface finish, which results from hot rolling to the specified thickness, followed by annealing and descaling. With sheets/coils/strips types, No. 1 finish stainless steel is characterized by its rough, dull, and non-uniform appearance. It is generally used in industrial applications where the surface finish is not critical, such as chemical tanks, piping, heat exchangers, equipment for elevated temperature service, and checker plates.

Manufacturing process:

At first, stainless steel is heated and then rolled at a high temperature to achieve the desired thickness. Secondly, the hot-rolled steel is annealed in a controlled atmosphere to relieve internal stresses and achieve a uniform microstructure. At last, the surface is descaled to remove the oxide layer that forms during annealing.

Standard Sizes

Sheets/Plates: 1000mm*2000mm, 1219mm*2438mm, 1219mm*3048mm, 1500mm*3000mm

Coils: prime materials. 1000mm*C, 1219mm*C, etc.

Available Size

No.1 finish stainless steel results from hot rolling to the specified thickness, followed by annealing and descaling. A customized specific cut-to-width is acceptable, but the fee will be high. Its rough surface provides good resistance to wear and tear, making it suitable for heavy-duty applications. The available thickness ranges from 4.00 to 12.00mm. If your thickness is over this scope, please consult us for an assessment.

|

Grade |

Types |

Thickness |

Width(mm) |

||||

|

1000 |

1219 |

1250 |

1500 |

Customized |

|||

|

201 |

Sheet/Coil |

3.60-14.00 |

◑ |

★ |

★ |

★ |

☆ |

|

304 |

Sheet/Coil |

2.70-14.00 |

◑ |

★ |

★ |

★ |

☆ |

|

316L |

Sheet/Coil |

2.70-14.00 |

◑ |

★ |

★ |

★ |

☆ |

| PS: "★" indicates available. "☆" indicates unavailable. "◑" indicates the one to be confirmed. | |||||||

Application

As the unique surface of the hot-rolled stainless steel, No.1 finish is a rough, dull surface compared to the more polished finishes. Generally, No.1 finish stainless steel is suitable for applications that do not require a smooth or reflective surface. Therefore, it is commonly used in industrial or structural uses where cost-effectiveness is more important than aesthetics. If you are a stainless steel manufacturer, No.1 finish stainless steel can also be a base material for further processing or finishing.

Competitive Advantages

Topson knows it is important for customers and their equipment or projects to get the best quality from stainless steel. The No.1 finish stainless steel that Topson produces helps to make this happen. In addition, with the expert processing technique, we can etch, polish, or further process according to different requirements. If you are interested in our quality stainless steel, contact Topson!

● We are able to provide our customers with the best quality raw materials, which come from JISCO, TISCO, BAOSTEEL, and POSCO.

● Quality inspection runs through every production step, from raw materials to finished products.

● Continuously improve the manufacturing process management, increase the yield rate to 99%, and enhance the overall competitiveness.

● Diversified equipment and customized products increase competitiveness in the global market.

● We provide fast quotations and the best after-sales service, providing customers with overall solutions and technical exchanges.

No.1 Finish Stainless Steel VS 2B finish stainless steel

● No.1 finish stainless steel belongs to hot rolled stainless steel, suitable for applications with low surface requirements. 2B finish stainless steel is achieved by cold-rolling and light polishing, making it more suitable for applications requiring a better appearance.

● No.1 stainless steel finish is rougher and duller, while the 2B finish is smoother and slightly reflective.

● No.1 finish stainless steel is ideal for functional, industrial, and structural applications, while 2B finish stainless steel is better suited for decorative, architectural, and consumer-oriented uses.

● In terms of hardness, 2B finish stainless steel may be slightly harder, and No.1 stainless steel is slightly softer.

● Regarding ductility, the ductility of No.1 stainless steel is lower than that of 2b finish stainless steel. However, No.1 stainless steel is stronger than 2b finish stainless steel.

CONTACT US

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China