Topson Group Provides Quality Stainless Steel Decorative Sheets Gobally.

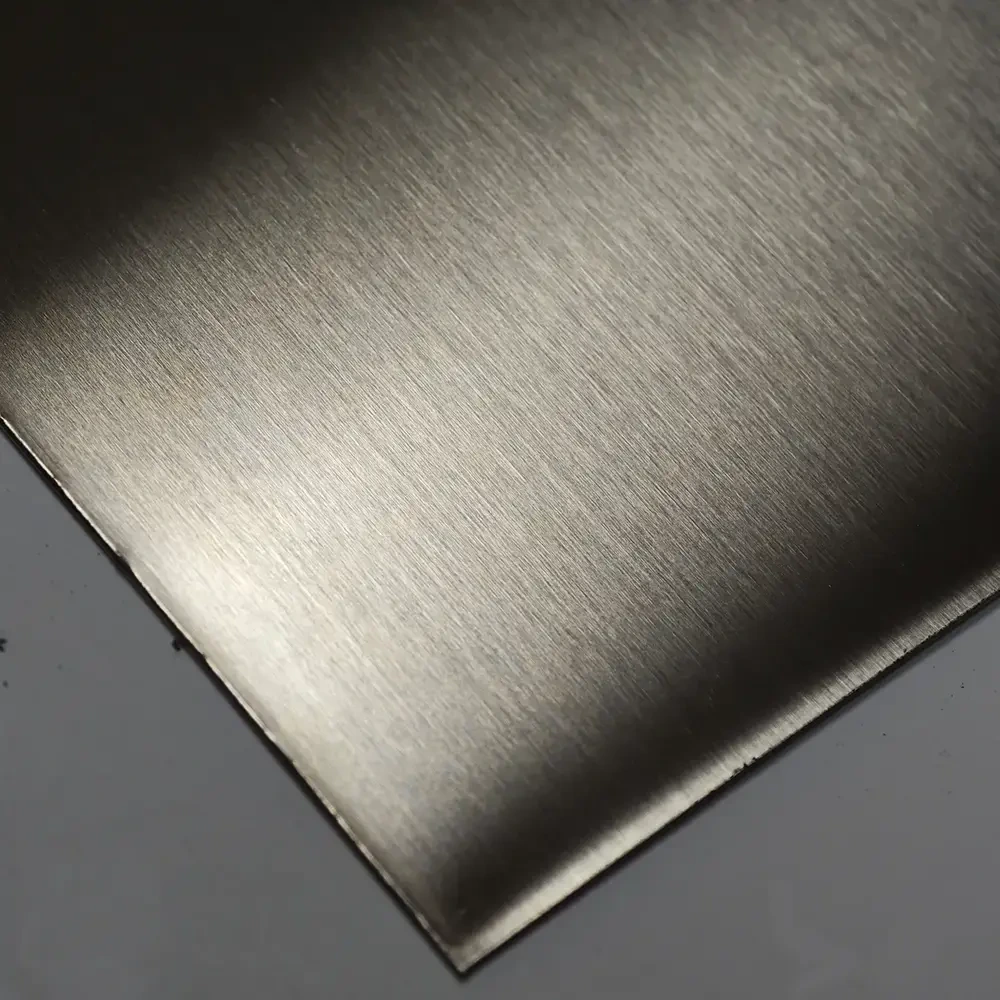

Scotch Brite Finish Stainless Steel

Scotch Brite finish (SB Finish) is a semi-dull brushed finish with uniform grain, which is finer than No.4, hairline, and straight-brushed. Sotch Brite finish stainless steel has smooth, soft, and exquisite grains with a low-reflectivity and unidirectional texture.

Process:

The grain of Scotch Brite stainless steel finish is formed by drawing the surface of the plate or sheet through the rotation of the non-woven roller containing abrasives. It is shallow and smooth.

Standard Sizes

Sheets/Plates: 1000mm*2000mm, 1219mm*2438mm, 1219mm*3048mm, 1500mm*3000mm

Coils: prime materials. 1000mm*C, 1219mm*C, etc.

Available Size

Our Scotch Brite finish processing machine consists of multiple wire-drawing rolls, simultaneously achieving the processing requirements of coarse wire, fine wire and polishing. Since the wire-drawing roll has a certain elasticity, it can be processed even if the plate has a certain curvature or small protrusions. At Topson, the available thickness is 0.40mm - 3.00mm.

|

Grade |

Types |

Thickness |

Width(mm) |

||||

|

1000 |

1219 |

1250 |

1500 |

Customized |

|||

|

201(J2) |

Sheet/Coil |

0.40-3.00 |

★ |

★ |

★ |

☆ |

★ |

|

304/304L |

Sheet/Coil |

0.40-3.00 |

★ |

★ |

★ |

☆ |

★ |

|

316L |

Sheet/Coil |

0.40-3.00 |

☆ |

★ |

★ |

☆ |

★ |

|

410 |

Sheet/Coil |

0.40-3.00 |

★ |

★ |

★ |

☆ |

★ |

|

430 |

Sheet/Coil |

0.40-3.00 |

★ |

★ |

★ |

☆ |

★ |

Application

Scotch Brite stainless steel finish hides scratches and fingerprints well, making it ideal for high-traffic areas. Our scotch brite finish stainless steel is commonly used for internal architectural elements, elevator panels, kitchen equipment, cladding, facades, hotel lobbies, and commercial buildings.

Competitive Advantages

Topson knows it is important for customers and their architectural projects to get the right look from stainless steel. For decades, Topson Group has perfected its stainless steel surface processing capabilities, including slitting, cutting, sanding, and brushing, 8K, PVD coating, bead blasting, etching, and other types of surface finishing technology. If you are interested in our decorative stainless steel, feel free to contact us!

● We are able to provide our customers with the best quality raw materials, which come from JISCO, TISCO, BAOSTEEL, and POSCO.

● Quality inspection runs through every production step, from raw materials to finished products.

● Continuously improve the manufacturing process management, increase the yield rate to 99%, and enhance the overall competitiveness.

● Diversified equipment and customized products increase competitiveness in the global market.

● The best quality, competitive price, and short delivery time help us become a long-term cooperative supplier for our customers.

● We provide fast quotations and the best after-sales service, providing customers with overall solutions and technical exchanges.

Production Lines

● Thickness: 0.30mm-5.0mm

● Width: Up to 1500mm

● Length: Up to 3000mm

● Available Finish: No.3, No.4, Hairline, Scotch Brite.

Why do People Choose Polishing

● Enhanced light reflection, making stainless steel products more visually attractive.

● Enhance the hardness and scratch resistance of stainless steel surface.

● Removes tiny bumps and burrs from stainless steel surfaces.

● Hides scratches and fingerprints well.

CONTACT US

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China