Topson Group Provides Quality Stainless Steel Decorative Sheets Gobally.

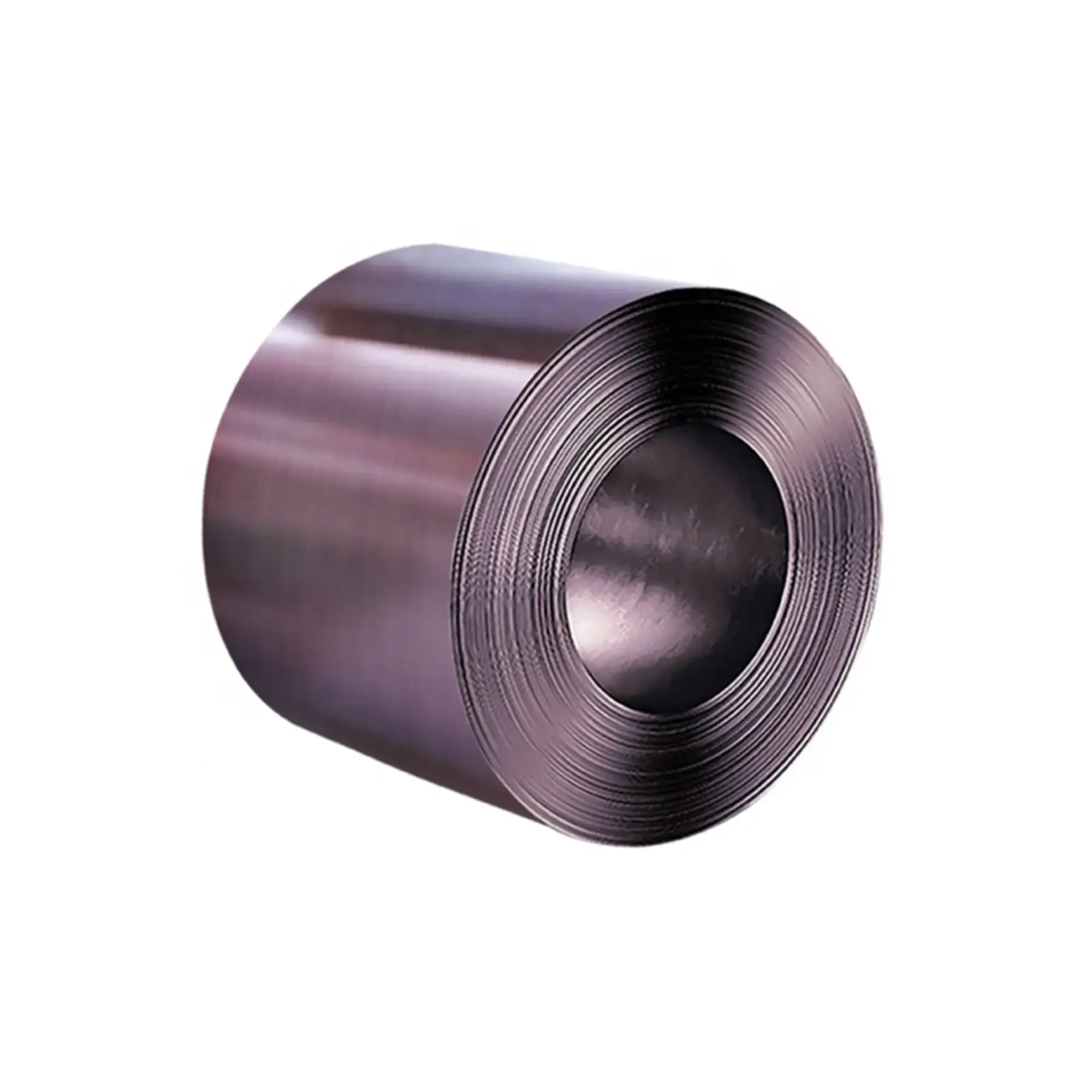

Satin Finish Coil

Satin finish is one type of brushed finish obtained by 150-180 grit abrasive. Its processing is similar with Scotch Brite finish, but its pattern is coarser than Scotch Brite finish. Satin finish stainless steel is characterized by short and parallel brushing lines. Unlike mirror finish, satin finish stainless steel has less reflectivity and glossiness, offering a more subtle and understated appearance.

Standard Sizes

Prime materials. 1000mm*C, 1219mm*C, 1500mm*C, etc.

Available Size

Satin finish is any that results in a surface featuring a more grain-like, brushed, or grooved appearance in all surface treatment types. It is considered a random orbital finish achieved by sanding with coated abrasive pads, with no specific direction of the grain. To speak with the Topson Stainless team about your project, or if you have any questions regarding satin finishing or finish options, request a quote.

|

Grade |

Types |

Thickness |

Width(mm) |

||||

|

1000 |

1219 |

1250 |

1500 |

Customized |

|||

|

201(J2) |

Coil |

0.40-3.00 |

★ |

★ |

★ |

★ |

★ |

|

304/304L |

Coil |

0.40-3.00 |

★ |

★ |

★ |

★ |

★ |

|

316L |

Coil |

0.40-3.00 |

☆ |

★ |

★ |

★ |

★ |

|

410 |

Coil |

0.40-3.00 |

★ |

★ |

★ |

★ |

★ |

|

430 |

Coil |

0.40-3.00 |

★ |

★ |

★ |

★ |

★ |

Application

While satin finishes still reflect light and produce a gleaming effect, they do not achieve the same high shine as mirror finishes. Satin finishes may be desirable for a variety of reasons, including lower maintenance requirements. In addition, its duller, more matte appearance makes it better for areas with a large amount of light to reduce glare. Therefore, this particular finish is often applied to a variety of metal types for use in elevators and escalators.

Above sheet is satin finish. Below sheet is No.4 finish.

Competitive Advantages

Topson Group knows it is important for customers and their architectural projects to get the right look from stainless steel. Regarding satin finish, we strictly control the quality of each step of stainless steel processing, which ensures its integrated performance such as corrosion resistance, coating stickiness, etc. If you are interested in our satin finish stainless steel, just feel free to contact Topson!

● We are able to provide our customers with the best quality raw materials, which come from JISCO, TISCO, BAOSTEEL, and POSCO.

● Quality inspection runs through every production step, from raw materials to finished products.

● Continuously improve the manufacturing process management, increase the yield rate to 99%, and enhance the overall competitiveness.

● The best quality, competitive price, and short delivery time help us become a long-term cooperative supplier for our customers.

● We provide fast quotations and the best after-sales service, providing customers with overall solutions and technical exchanges.

Production Lines

● Machine: Stainless Steel Coil Polishing Line

● Thickness: 0.40mm-3.0mm

● Width: Up to 1500mm

● Length: Up to 3000mm

● Fineness of the textures can be adjusted.

Why do People Choose Brushing/Polishing

● Increased stainless steel's surface adhesion is conducive to subsequent coloring treatment.

● Achieved through brushing/polishing stainless steel with fine abrasives to create a consistent, satin-like texture.

● Enhanced light reflection, making stainless steel products more visually attractive.

● Enhance the hardness and scratch resistance of stainless steel surface.

● Removes tiny bumps and burrs from stainless steel surfaces.

● Hides scratches and fingerprints well.

CONTACT US

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China