Topson Group Provides Quality Stainless Steel Decorative Sheets Gobally.

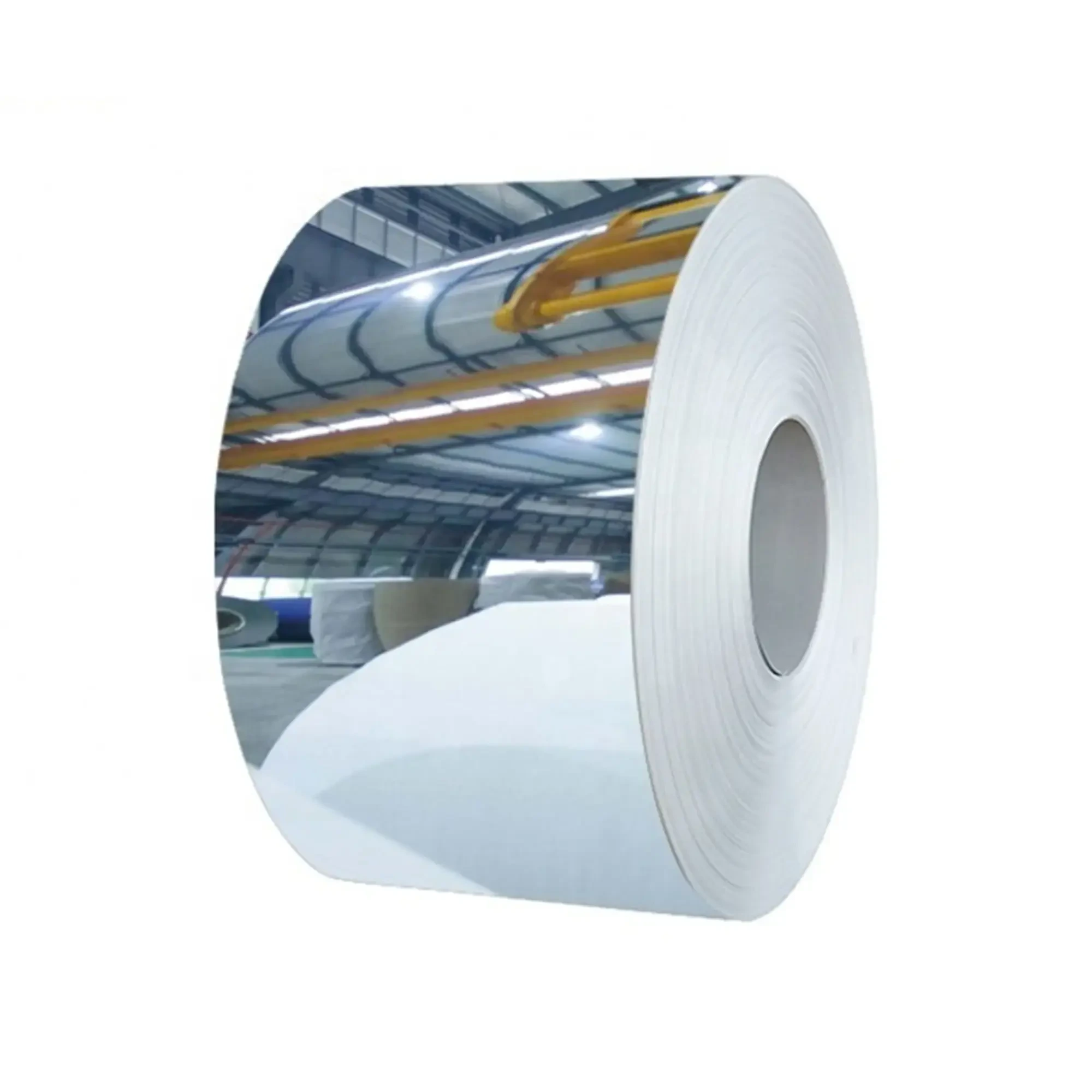

8K Coil - 201, 304, 316l, 430

"Mirror" refers to the surface state of stainless steel. In the stainless steel industry, "Mirror" should be classified as an "8K" surface. At TOPSON, our mirror stainless steel is divided into 6K, 8K, 10K, and 12K. Generally, 6K is general grinding, 8K is fine grinding, and 10K is super fine grinding.

Another surface similar to the mirror state is BA (Bright Anealing). BA finish is a bright treatment added to the 2B plate. BA finish can also reflect the portrait, but the overall clarity could be better than the mirror stainless steel.

Standard Sizes

Prime materials. 1000mm*C, 1219mm*C, 1500mm*C, etc.

Grade: SS201, SS304, SS316L, SS430.

Available Size

8K stainless steel is polished based on 2B and BA. Topson also provides 6K, 7K, 8K, and 10K finish. 8K and 10K are called Super Mirror, produced by finer abrasives and finished with extremely fine buffing compounds. Besides raw color, we have an independent PVD line that can achieve a 0.8-1.2uM colored coating layer.

|

Grade |

Types |

Thickness |

Width(mm) |

||||

|

1000 |

1219 |

1250 |

1500 |

Customized |

|||

|

201(J2) |

Coil |

0.30-5.00 |

★ |

★ |

★ |

★ |

◑ |

|

304/304L |

Coil |

0.30-5.00 |

★ |

★ |

★ |

★ |

◑ |

|

316L |

Coil |

0.30-5.00 |

◑ |

★ |

★ |

★ |

◑ |

|

410 |

Coil |

0.30-5.00 |

★ |

★ |

★ |

★ |

◑ |

|

430 |

Coil |

0.30-5.00 |

★ |

★ |

★ |

★ |

◑ |

| PS: "★" indicates available. "☆" indicates unavailable. "◑" indicates the one to be confirmed. | |||||||

Application

With its perfect reflective quality, mirror finish stainless steel is widely used in the ceilings of food preparation areas, architectural wall cladding, coping, trim, and artistic objects. We adopt a chemical wet polishing method to produce mirror stainless steel. Unlike dry polishing, wet polishing can create a nondirectional mirror finish that is transparent without any line marks. For more details about mirror stainless steel, contact us at your earliest convenience!

Competitive Advantages

Topson knows it is important for customers and their architectural projects to get the right look from stainless steel. We adopt a chemical wet polishing method to produce mirror stainless steel that is transparent without any line marks. If you are interested in our mirror stainless steel, just feel free to contact Topson!

● We are able to provide our customers with the best quality raw materials, which come from JISCO, TISCO, BAOSTEEL, and POSCO.

● Quality inspection runs through every production step, from raw materials to finished products.

● Continuously improve the manufacturing process management, increase the yield rate to 99%, and enhance the overall competitiveness.

● Diversified equipment and customized products increase competitiveness in the global market.

● The best quality, competitive price, and short delivery time help us become a long-term cooperative supplier for our customers.

● We provide fast quotations and the best after-sales service, providing customers with overall solutions and technical exchanges.

Production Lines

● Thickness: 0.30mm-3.0mm

● Width: Up to 1500mm

● Length: Up to 6000mm

● Finish: 6K, 7K, 8K, 10K, 12K

● Production Time: 7-21 days

● Sheet Size: 1000 x 2000mm, 1219 x 2438mm ( 4ft x 8ft ), 1219 x 3048mm ( 4ft x 10ft ), 1500 x 3000mm

● Packing:

1) 2 layers PE foils for protection

2) Waterproof paper for firm package

3) Thick wooden plates to cover

4) Metal pallet for LCL, and wooden pallets for FCL

Why do People Choose Mirror Polishing

● Mirror stainless steel has a surface as reflective as glass mirrors, but it is easily fabricated and not easily shattered.

● Mirror polishing creates a high gloss, reflective surface that enhances the visual appeal of the material. It gives the piece a luxurious and sophisticated look.

● The smooth, non-porous surface is easy to clean and disinfect, making it ideal for environments where hygiene is crucial, such as kitchens, laboratories, and medical facilities.

● Mirror polishing can be applied to different metals and surfaces, allowing for customization to meet specific design and functional requirements.

CONTACT US

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China