Topson Group Provides Quality Stainless Steel Decorative Sheets Gobally.

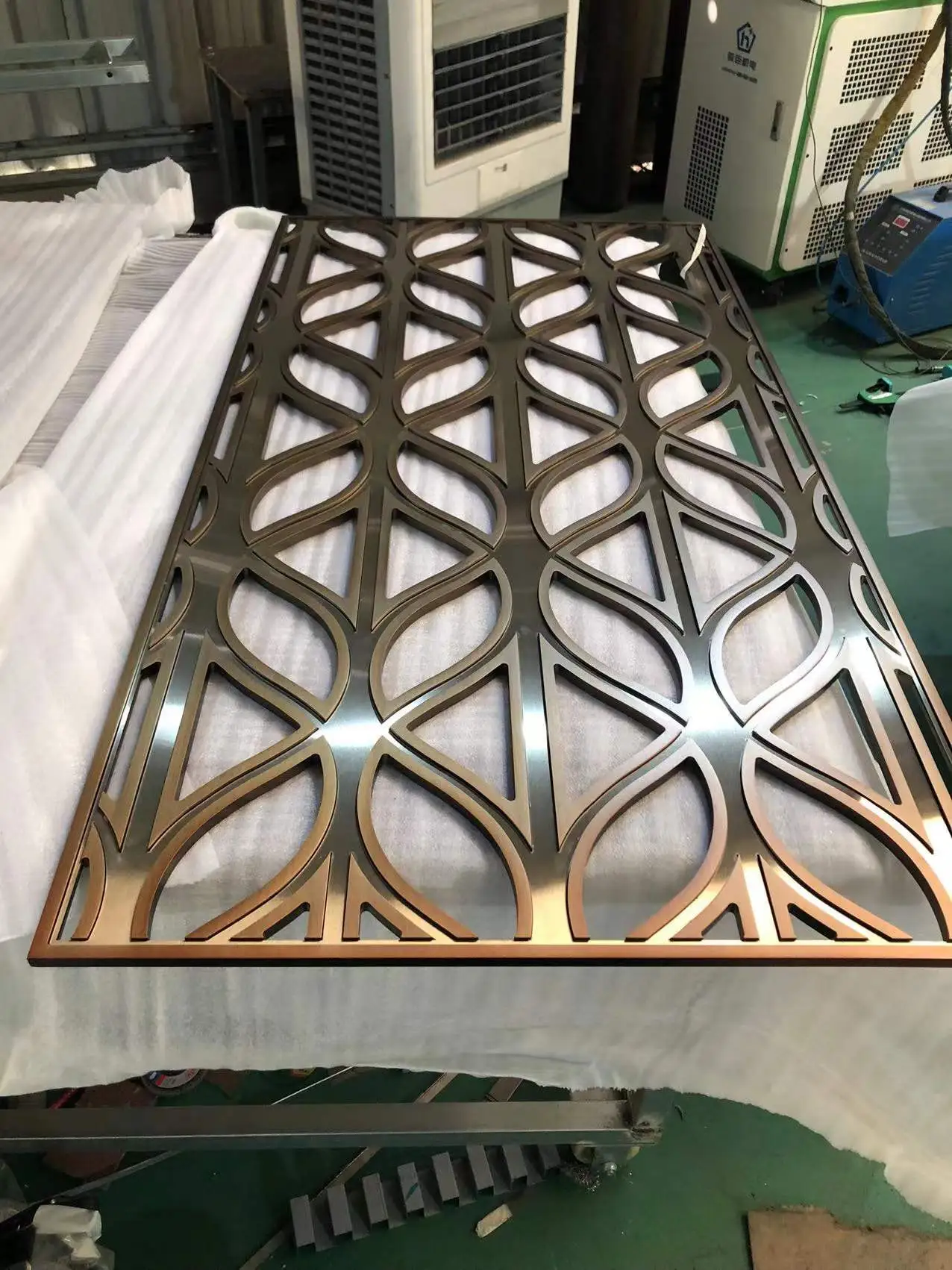

Stainless Steel Screen

Metal Products

Stainless steel screens, also known as stainless steel decorative lattice panels or partitions, are decorative components made of stainless steel materials. They are widely used in the field of modern architectural decoration, serving the dual purposes of space division and aesthetic enhancement.

Classification

-

By Material Selection

- Stainless steel tube-welded screens

- Stainless steel plate laser-cut screens

- Stainless steel flat bar-welded screens

-

By Welding Technology

- Seam-welded screens: Characterized by spot welding effects.

- Seamless-welded screens: Fabricated through full welding, grinding and polishing processes, leaving no visible gaps at the welding joints.

-

By Surface Finish

- Mirror-finish (high-gloss) stainless steel screens

- Brushed-finish (matte) stainless steel screens

-

By Surface Coating Color

- Available in a variety of colors such as rose gold, antique copper, vintage bronze, red antique copper, and titanium gold.

Material Characteristics

-

Durable and Sturdy Stainless steel boasts high hardness, making it resistant to deformation and damage. It also features excellent corrosion resistance and moisture resistance, ensuring a long service life.

-

Eco-friendly and Healthy Non-toxic and odorless, it does not release harmful substances, posing no threat to human health.

-

Easy to Clean Its smooth surface is not prone to dust and stain accumulation, and can be kept clean with simple wiping.

Processing Technology

-

Laser Cutting Technology After surface treatment, stainless steel plates are precisely cut with laser to create various exquisite patterns, followed by vacuum electroplating for color application.

-

Welding and Polishing Technology Stainless steel tubes or plates are first processed into desired shapes, then welded together. Subsequent processes including grinding, polishing and vacuum electroplating are carried out to achieve a smooth surface and bright, glossy color finish.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Related Surface Treatment

no data

Send a message

If you have any questions about our stainless steel sheets products or services, feel free to reach out to customer service team.

CONTACT US

>Tel: +86 0757 2939 7619

> Mob/Whatapp: +86 180 2414 5225

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China

Copyright © 2025 Foshan Topson Stainless Steel Co., Ltd. | Sitemap | Privacy Policy