Topson Group Provides Quality Stainless Steel Decorative Sheets Gobally.

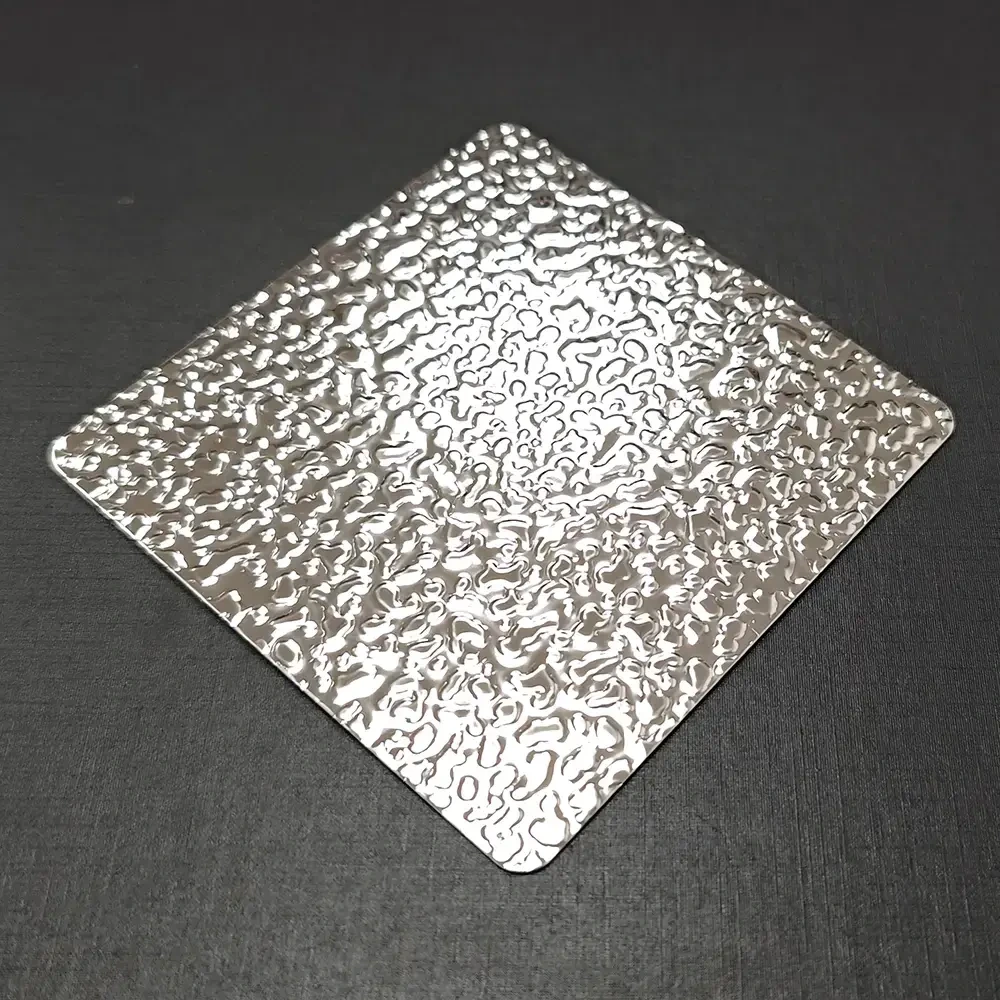

Small Water Ripple Stainless Steel

Mirror polishing enhances the reflective effect and adhesion, which is good for coloring. PVD coating will improve the steel's wear resistance and aesthetics. A nano-coating reduces smudges and fingerprints, especially for high-touch surfaces.

Available Material

- 304 stainless steel. The most common food grade stainless steel, good corrosion resistance.

- 316 stainless steel. Better corrosion resistance, suitable for high corrosion environment.

- 201 stainless steel. Lower cost, slightly weak corrosion resistance, suitable for general decoration.

Standard Sizes

Sheets/Plates: 1000mm*2000mm, 1219mm*2438mm, 1219mm*3048mm, 1500mm*3000mm

Coils: prime materials. 1000mm*C, 1219mm*C, etc.

Available Size

At Topson, the processing size of water ripple stainless steel sheet can be customized according to specific needs, but there are usually some common specifications and ranges.

|

Grade |

Types |

Thickness |

Width(mm) |

||||

|

1000 |

1219 |

1250 |

1500 |

Customized |

|||

|

201(J2) |

Sheet |

0.30-3.00 |

★ |

★ |

★ |

★ |

★ |

|

304/304L |

Sheet |

0.30-3.00 |

★ |

★ |

★ |

★ |

★ |

|

316L |

Sheet |

0.30-3.00 |

☆ |

★ |

★ |

★ |

★ |

Application

Water ripple stainless steel is often used in architectural decoration for external walls, interior walls, ceilings, etc., which can enhance the modern sense of architecture.

Competitive Advantages

Topson knows it is important for customers and their architectural projects to get the right look from stainless steel. Our quality inspection runs through every production step, from raw materials to finished products. If you are interested in our small water ripple stainless steel, just feel free to contact Topson!

● We are able to provide our customers with the best quality raw materials, which come from JISCO, TISCO, BAOSTEEL, and POSCO.

● Continuously improve the manufacturing process management, increase the yield rate to 99%, and enhance the overall competitiveness.

● Diversified equipment and customized products increase competitiveness in the global market.

● The best quality, competitive price, and short delivery time help us become a long-term cooperative supplier for our customers.

● We provide fast quotations and the best after-sales service, providing customers with overall solutions and technical exchanges.

CONTACT US

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China