Topson Group Provides Quality Stainless Steel Decorative Sheets Gobally.

Embossed Stainless Steel

Characteristics:

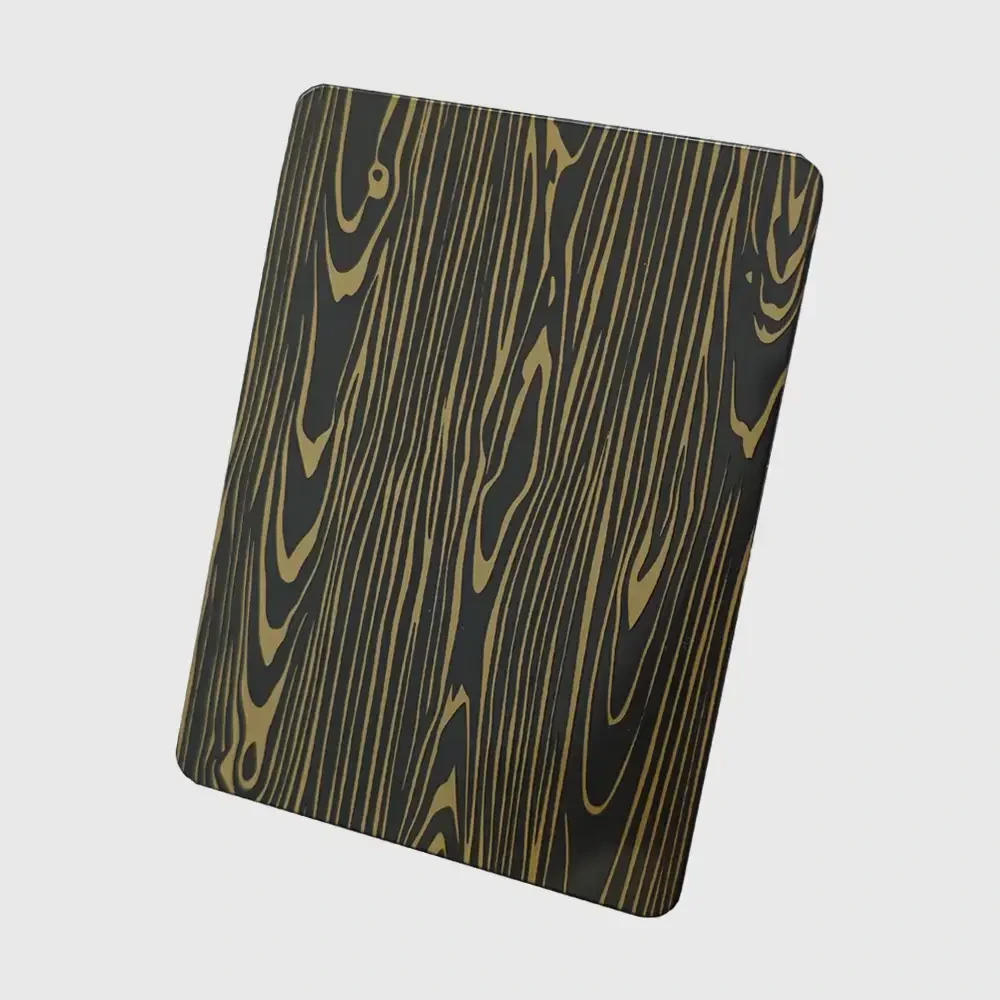

Combination of black and gold color is classic, luxurious and visually impactful, and it easily attracts attention. On the other hand, the dark color surface helps to hide fingerprints, smudges, and minor scratches, making it ideal for high-traffic areas or applications that require frequent handling.

Manufacturing Process:

The wood-like grain is achieved through an embossing process, where male and female roll molds are used to create it on the stainless steel sheets. And the colors are achieved by LIC Coating.

Available Size

|

Grade |

Types |

Thickness |

Width(mm) |

||||

|

1000 |

1219 |

1250 |

1500 |

Customized |

|||

|

201(J2) |

Sheet/Coil/Strip |

0.30-3.00 |

★ |

★ |

★ |

★ |

★ |

|

304/304L |

Sheet/Coil/Strip |

0.30-3.00 |

★ |

★ |

★ |

★ |

★ |

|

316L |

Sheet/Coil/Strip |

0.30-3.00 |

☆ |

★ |

★ |

★ |

★ |

|

410 |

Sheet/Coil/Strip |

0.30-3.00 |

★ |

★ |

★ |

★ |

★ |

|

430 |

Sheet/Coil/Strip |

0.30-3.00 |

★ |

★ |

★ |

★ |

★ |

Application

Embossed stainless steel is widely used across various industries due to its unique textured surface, which is created by pressing patterns or designs into the steel. It is often used in wall cladding, elevator interiors, ceiling panels, column covers, and signage.

Competitive Advantages

Topson knows it is important for customers and their architectural projects to get the right look from stainless steel. The embossed stainless steel sheets that Topson produces help to make this happen. After embossing, we also can color according to different requirements. If you are interested in our decorative stainless steel, just feel free to contact Topson!

● We are able to provide our customers with the best quality raw materials, which come from JISCO, TISCO, BAOSTEEL, and POSCO.

● Quality inspection runs through every production step, from raw materials to finished products.

● Continuously improve the manufacturing process management, increase the yield rate to 99%, and enhance the overall competitiveness.

● Diversified equipment and customized products increase competitiveness in the global market.

● The best quality, competitive price, and short delivery time help us become a long-term cooperative supplier for our customers.

● We provide fast quotations and the best after-sales service, providing customers with overall solutions and technical exchanges.

Why do People Choose Embossing

● With its uneven texture, embossed panels remain sanitary and easier to clean longer than non-embossed finished panels.

● The concave and convex texture effectively improves the anti-skid performance of the plate, especially suitable for places where anti-skid treatment is required.

● Embossed finishes can add a tactile element to a surface to enhance the visual appeal.

● Embossed finishes can help to hide scratches or dents.

● Unlike non-embossed finished panels, the embossed stainless steel plate cannot easily accumulate dust. MIRINZ has made a test that exposes the embossed wall panels at the eye, waist and knee level to dirt, blood, excrement and various animal products. This test proves that the embossed panel was clean and unstained during the trial and did not show signs of visible damage.

CONTACT US

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China