Topson Group Provides Quality Stainless Steel Decorative Sheets Gobally.

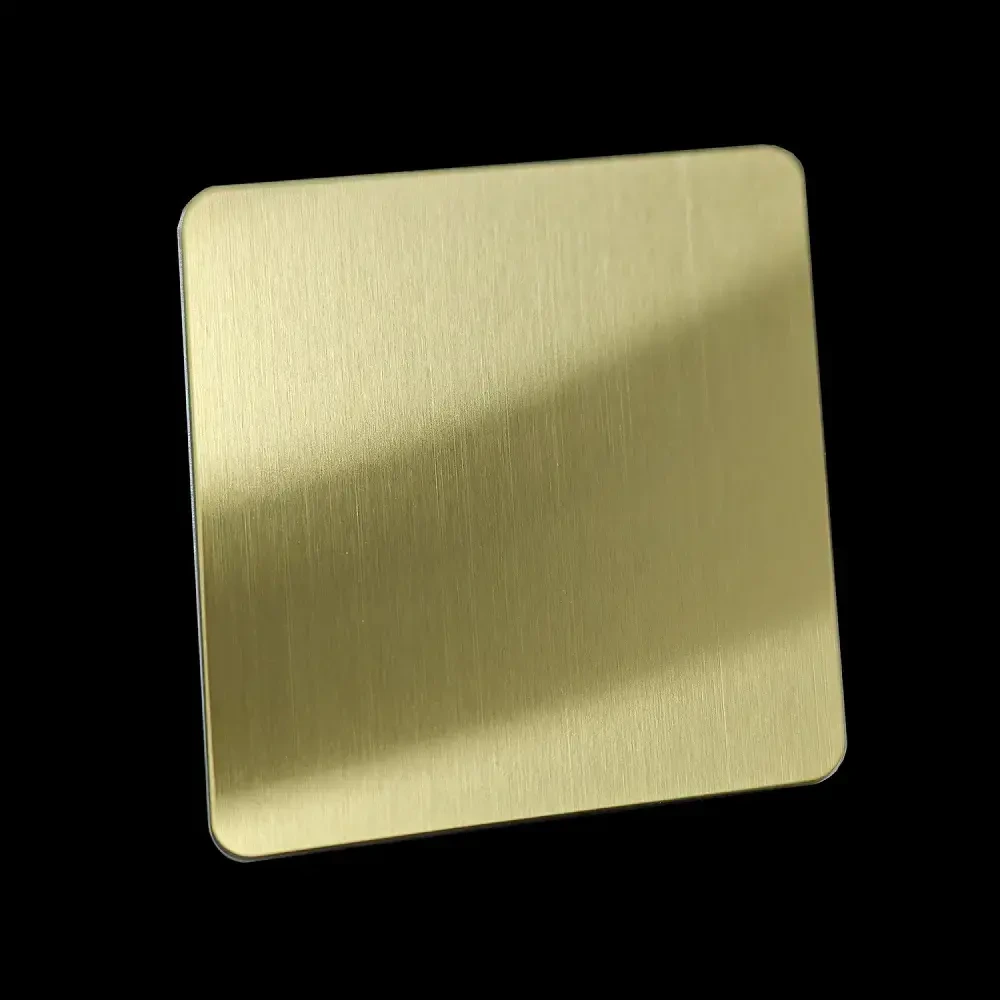

Hairline Finish Stainless Steel

Standard Sizes

Sheets/Plates: 1000mm*2000mm, 1219mm*2438mm, 1219mm*3048mm, 1500mm*3000mm

Coils: prime materials. 1000mm*C, 1219mm*C, etc.

Available Size

Processing hairline finish, we will start with using coarse abrasives to grind to remove deep scratches and imperfections. Then, brush the surface with fine grit to create parallel lines. Finally, to achieve a more refined look, we will use very fine abrasives to make the final polishing. At Topson, the available thickness is 0.30mm - 10.00mm.

|

Grade |

Types |

Thickness |

Width(mm) |

||||

|

1000 |

1219 |

1250 |

1500 |

Customized |

|||

|

201(J2) |

Sheet/Coil/Strip |

0.30-10.00 |

★ |

★ |

★ |

★ |

★ |

|

304/304L |

Sheet/Coil/Strip |

0.30-10.00 |

★ |

★ |

★ |

★ |

★ |

|

316L |

Sheet/Coil/Strip |

0.30-10.00 |

☆ |

★ |

★ |

★ |

★ |

|

410 |

Sheet/Coil/Strip |

0.30-10.00 |

★ |

★ |

★ |

★ |

★ |

|

430 |

Sheet/Coil/Strip |

0.30-10.00 |

★ |

★ |

★ |

★ |

★ |

Production Lines

● Equipment: Stainless Steel Coil Polishing Line

● Thickness: 0.30mm-3.0mm

● Width: Up to 1500mm

● Length: Up to 3000mm

● Available Finish: Hairline (HL), Satin (NO.4), Scotch Brite (SB)

● Available Colors: Champagne, Gold, Black, Blue, Purple, Rose Gold, etc.

● Fineness of the textures can be adjusted.

Competitive Advantages

Topson knows that competitive prices are as important as high quality for stockists and wholesales. With an advanced production line, Topson is able to offer the most competitive hairline finish stainless steel whether you need coils or sheets.

● We are able to provide our customers with the best quality raw materials, which come from JISCO, TISCO, BAOSTEEL, and POSCO.

● At Topson, we adopt oil polishing to achieve a matte finish, such as satin, scotch brite, and hairline. It will be brighter than regular polishing. This means it has a stronger metallic sheen.

● Continuously improve the manufacturing process management, increase the yield rate to 99%, and enhance the overall competitiveness.

● Diversified equipment and customized products increase competitiveness in the global market.

● The best quality, competitive price, and short delivery time help us become a long-term cooperative supplier for our customers.

● We provide fast quotations and the best after-sales service, providing customers with overall solutions and technical exchanges.

Application

The reasons why people choose hairline finish are often related to their understated look, ability to hide fingerprints, and improved grip. Hairline stainless steel is commonly applied in elevator panels, railings, appliances, and industrial equipment.

Why do People Choose Polishing

● Achieved through polishing stainless steel with fine abrasives to create a consistent, satin-like texture.

● Enhance the hardness and scratch resistance of stainless steel surface.

● Enhanced light reflection, making stainless steel products more visually attractive.

● Removes tiny bumps and burrs from stainless steel surfaces.

● Hides scratches and fingerprints well.

● Combined with PVD coaing can enhance the wear resistance and hardness of stainless steel, making it more durable and long-lasting.

CONTACT US

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China