Topson Group Provides Quality Stainless Steel Decorative Sheets Gobally.

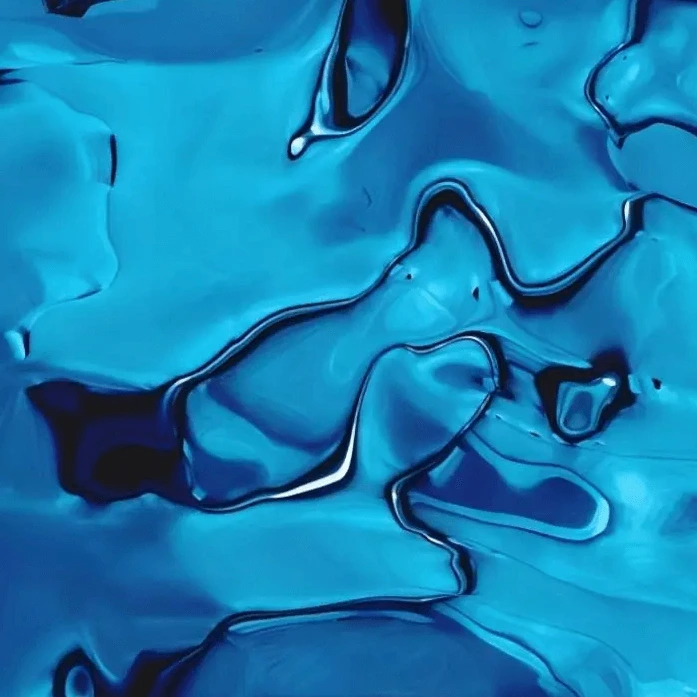

Blue Water Ripple Stainless Steel Sheet

▉ Water ripple stainless steel is a type of stainless steel sheet that features a unique pattern resembling the ripples created by water. It is also referred to as water wave stainless steel or water wave pattern stainless steel.

▉ Versatility

Water ripple stainless steel sheets find applications in various industries, including interior design, ceilings, decorative accents, and more. They are commonly used for wall panels, ceiling cladding, elevator interiors, column covers, and other decorative elements.

▉ Our solutions are based on stainless steel grades 201, 304, and 316 for outdoor applications, particularly facade construction. We have sufficient production capacities to guarantee the fastest delivery service possible.

▉ TOPSON's controlled and precisely recorded production is based on 14 years of experience in stainless steel polishing, surface roughness depth and gloss measurement, and the professional evaluation of the visual appearance.

TOPSON's Capacities

Our blue water ripple pattern is achieved through surface treatment processes, including stamping and PVD or LIC coating. It can be combined with an anti-fingerprint layer to improve the scratched resistance.

1. Large selection of water wave patterns.

2. Production according to customer specifications possible.

3. Values of each order and every individual sheet, ensuring max reproducibility.

4. Polishing is also possible on both sides of the stainless steel plate (Front + Reverse).

Product Parameters

|

Standard |

AISI, ASTM, GB, DIN, EN |

|

Grade |

201,304,316L,430, etc. |

|

Thickness |

0.5~3.0mm, other customized |

|

Size |

1000 x 2000mm, 1219 x 2438mm ( 4ft x 8ft ), 1219 x 3048mm ( 4ft x 10ft ), 1500 x 3000mm, other customized |

|

Surface finish |

BA, 6K, 8K |

|

Titanium Coating Colors |

Ti-gold, Champagne gold, Rose gold, Rose red, Wine red, Coffee, Pink, LIC Ti-black, PVD coating Ti-black, Jewelry blue, Emerald green, Violet, Red copper etc. |

|

Certificate |

SGS ROHS, SGS Abrasion Resistance, SGS Adhesion Test of Coating, SGS Natural Salt Spray Test |

CONTACT US

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China