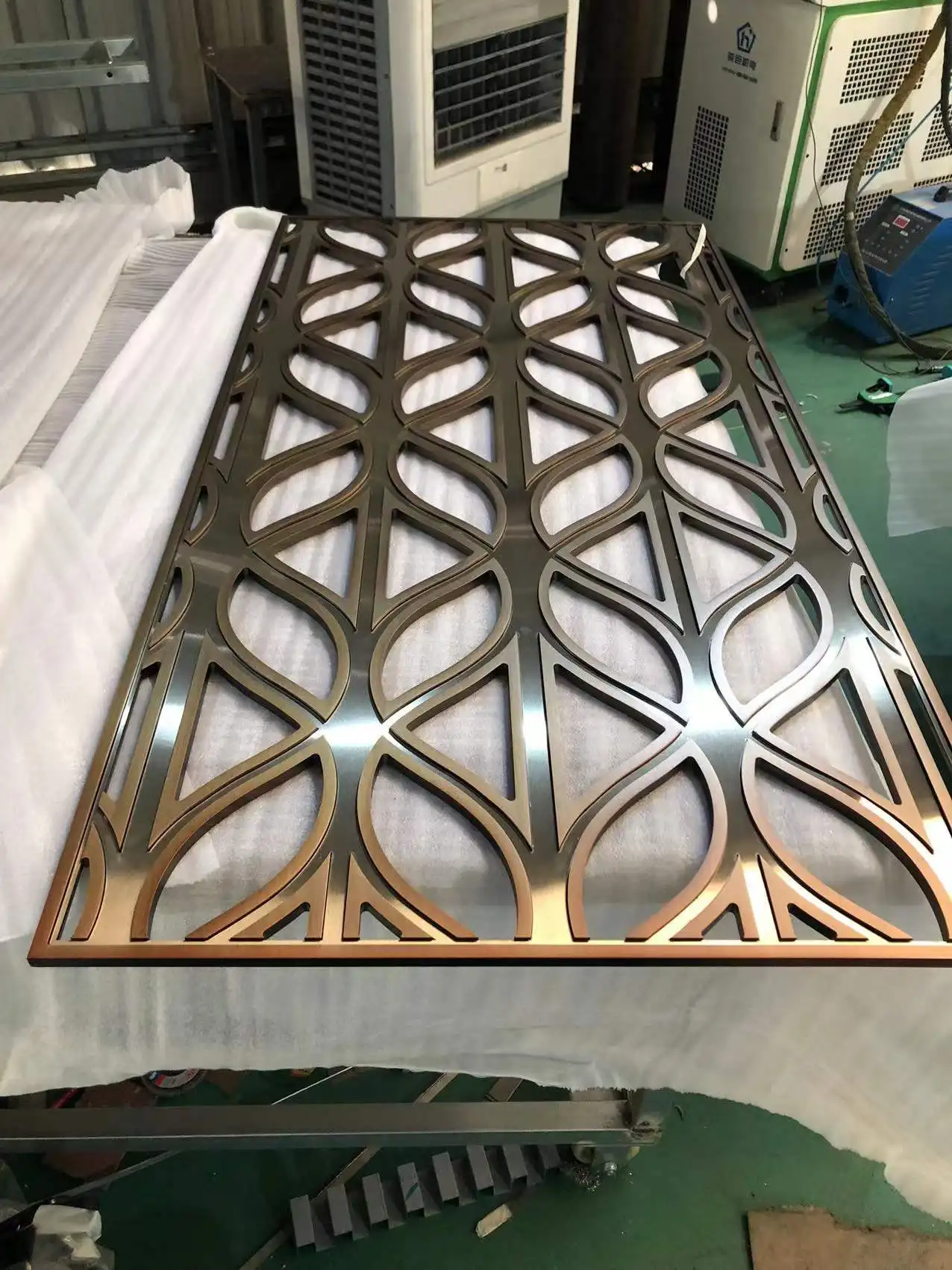

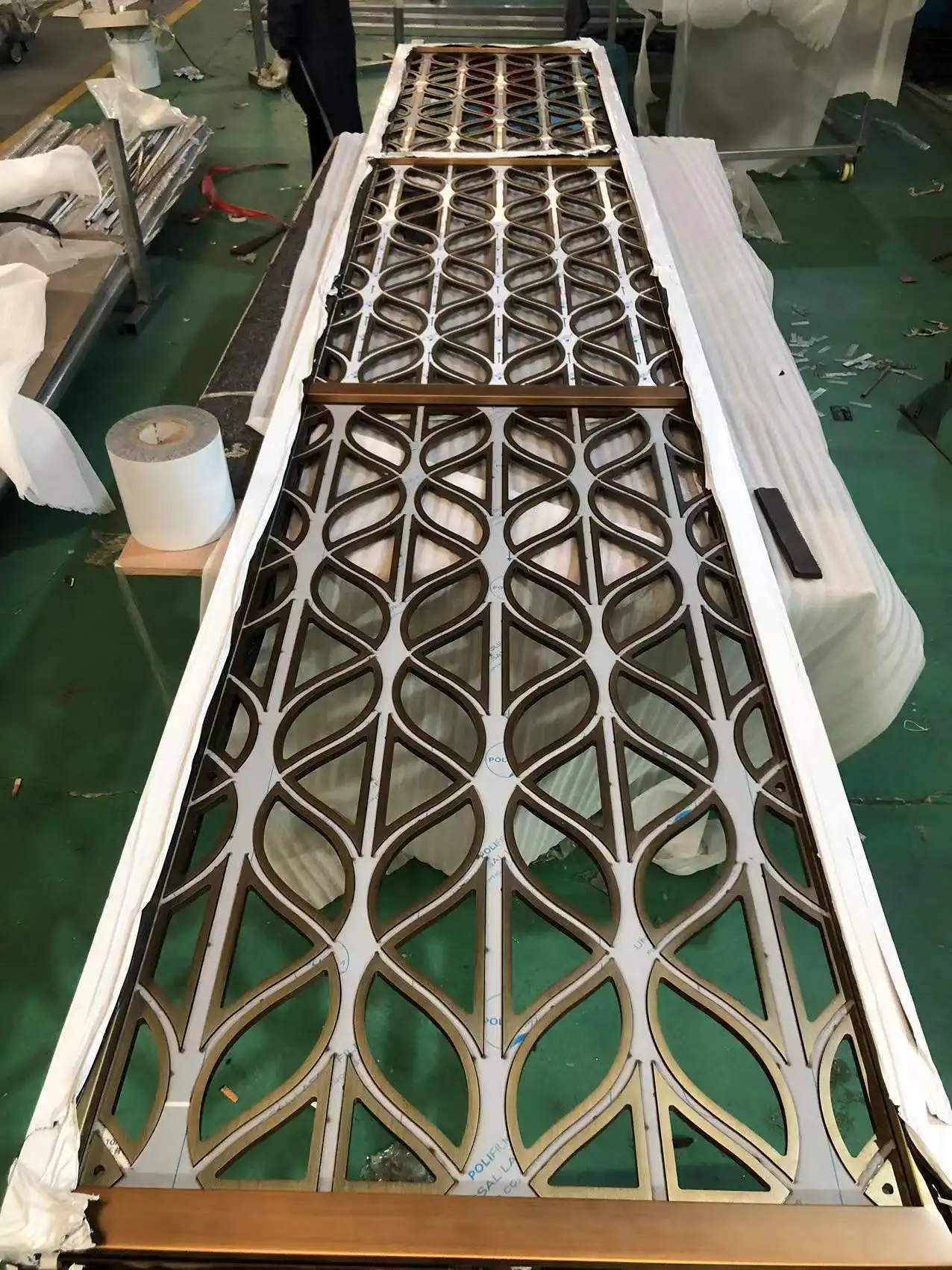

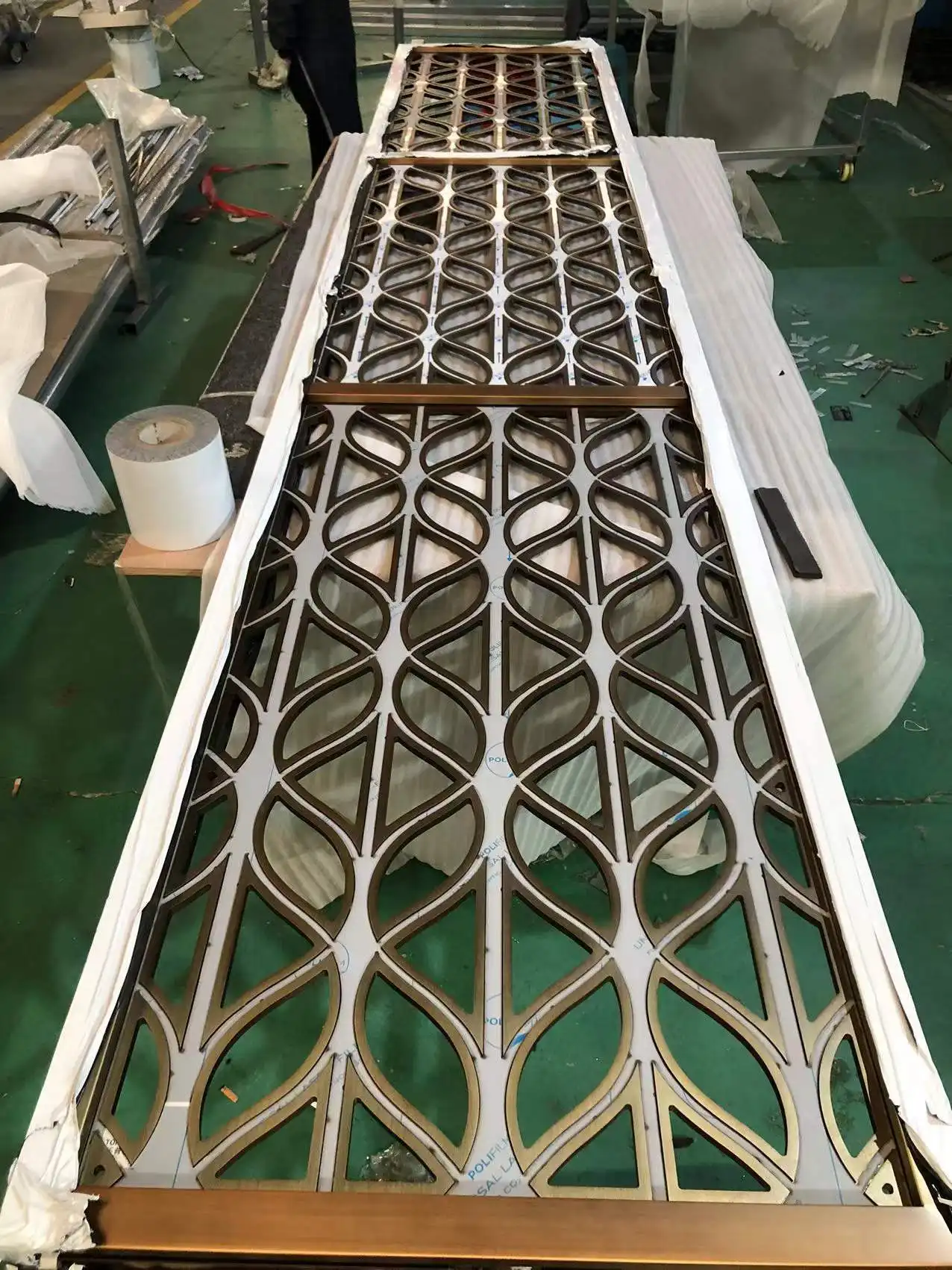

Topson Group Provides Quality Stainless Steel Decorative Sheets Gobally.

luxurious architectural metalwork chain for roofs

Certificates:

SGS,UL ISO 9001:2000,CE,KYNAR 500, etc

Feature:

Environmental Protection, Moistureproof,Good heat dissipation, Easy Processing, UV radiation.

Warranty:

Up to15 Years based on different coating

Usage:

Outdoor, Interior, Roof decoration, Outdoor Wall Cladding Decoration, Building Facades

Surface:

Mirror , satin, hairline, snow satin and so on

Place:

Building, Hotel, Office, Room, Apartment, Tower, Mall etc

Material:

Stainless steel , Aluminum, metal...

Advantages:

Customized Pattern ,Good strength ,Simple installation, Low maintenance cost

Panel Dimension:

Customized size

architectural metalwork

description

The product is strongly resistant to rust. The materials of the frame adopt reinforced aluminum alloy whose surface has been treated with anodized finish. Its germ resistance makes this product ideal for use in hygienic applications such as kitchen, public restaurant, bathroom, etc

architectural metalwork

SPECIFICATIONS

| Certificates | SGS,UL ISO 9001:2000,CE,KYNAR 500, etc |

|---|---|

| Feature | Environmental Protection, Moistureproof,Good heat dissipation, Easy Processing, UV radiation. |

| Warranty | Up to15 Years based on different coating |

| Usage | Outdoor, Interior, Roof decoration, Outdoor Wall Cladding Decoration, Building Facades |

| Place | Building, Hotel, Office, Room, Apartment, Tower, Mall etc |

| Material | Stainless steel , Aluminum, metal... |

| Surface | Mirror , satin, hairline, snow satin and so on |

| Advantages | Customized Pattern ,Good strength ,Simple installation, Low maintenance cost |

| Panel Dimension | Customized size |

The product had passed the SGS Natural Salt Spray Test, which means it is acid and alkali resistant. Any scratch on its surface can be easily polished to hide the scratch. The coating applied on its surface makes it resistant from oxidization.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

CONTACT US

>Tel: +86 0757 2939 7619

> Mob/Whatapp: +86 180 2414 5225

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China

Copyright © 2025 Foshan Topson Stainless Steel Co., Ltd. | Sitemap | Privacy Policy