Topson Group Provides Quality Stainless Steel Decorative Sheets Gobally.

Topson widely used steel safety grating Supply for office

Certificates:

SGS,UL ISO 9001:2000,CE,KYNAR 500, etc

Warranty:

Up to15 Years based on different coating

Place:

Building, Hotel, Office, Room, Apartment, Tower, Mall etc

Advantages:

Corrosion and Chemical Resistant; High strength – to- weight ratio; Impact resistance; Fire resistance;Ergonomic; Slip & falls-resistant; Long time Life Span; Maintenance Free; Safety; Low Cost effectiveness;

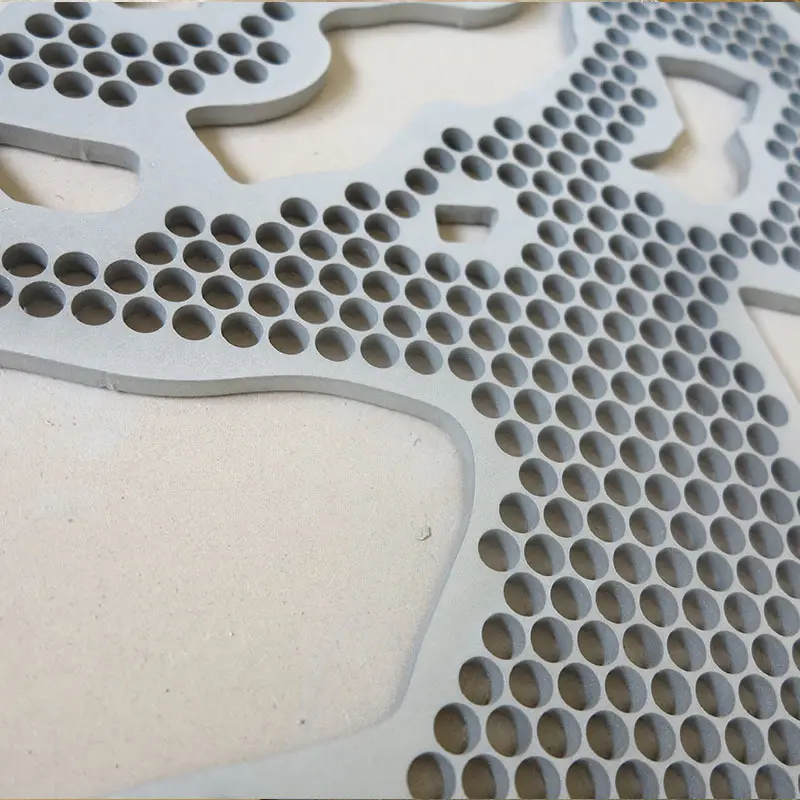

steel safety grating

description

The filling material and the fabric are perfectly coordinated. As a result, this product performs to its very best. Its germ resistance makes this product ideal for use in hygienic applications such as kitchen, public restaurant, bathroom, etc

steel safety grating

SPECIFICATIONS

| Certificates | SGS,UL ISO 9001:2000,CE,KYNAR 500, etc |

|---|---|

| Warranty | Up to15 Years based on different coating |

| Place | Building, Hotel, Office, Room, Apartment, Tower, Mall etc |

| Advantages | Corrosion and Chemical Resistant; High strength – to- weight ratio; Impact resistance; Fire resistance;Ergonomic; Slip & falls-resistant; Long time Life Span; Maintenance Free; Safety; Low Cost effectiveness; |

It comes with different surface treatments such as hairline, mirror, or bead blast. It is certified under SGS Abrasion Resistance and SGS Adhesion Test of Coating. It is also widely used in the aviation industry due to its added strength without adding too much weight.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

CONTACT US

>Tel: +86 0757 2939 7619

> Mob/Whatapp: +86 180 2414 5225

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China

Copyright © 2025 Foshan Topson Stainless Steel Co., Ltd. | Sitemap | Privacy Policy