Topson Group Provides Quality Stainless Steel Decorative Sheets Gobally.

Topson sheetdecorative Supply for handrail

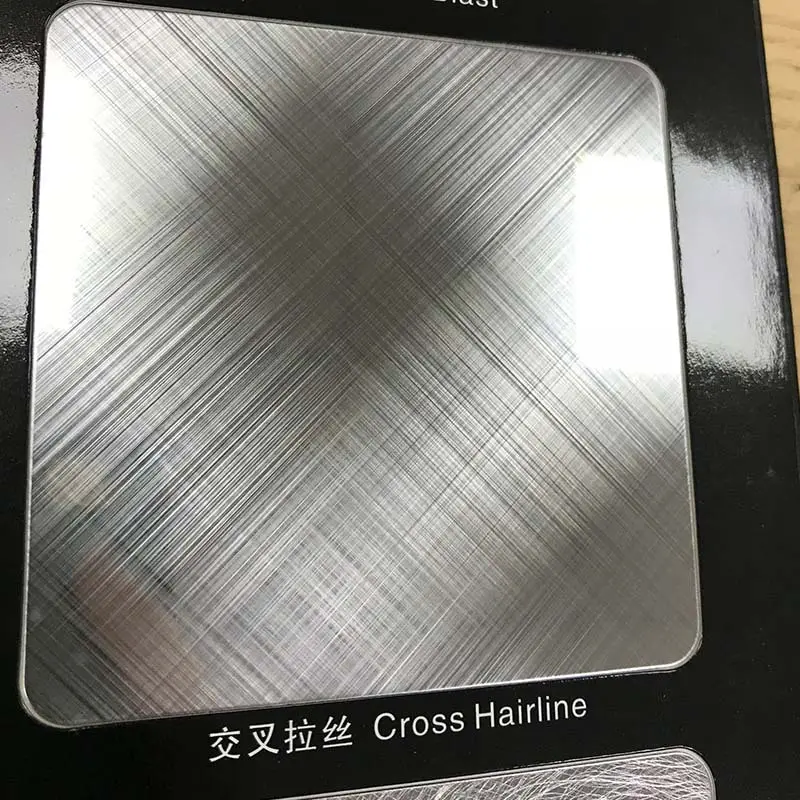

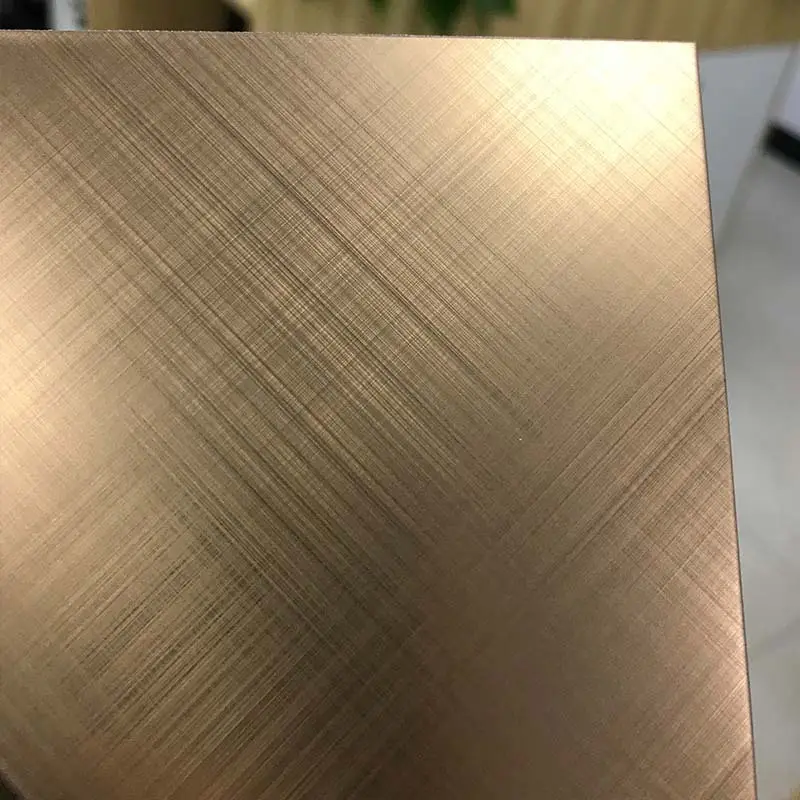

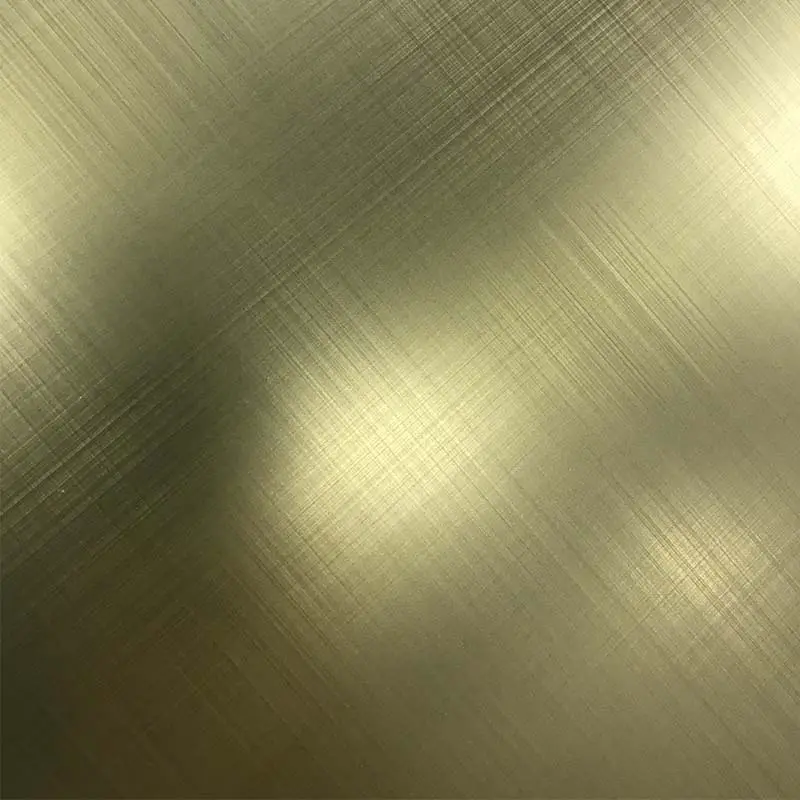

▉ Cross hairline finish is two hairline finish directions interlacedly showed on the surface. It is new finish. It is mostly applied with PVD coating colors and used a lot on architecture interior and exterior decoration.

Product Parameters

Standard | AISI, ASTM, GB, DIN, EN |

Grade | 201,304,316L,430, etc. |

Thickness | 0.5~3.0mm, other customized |

Size | 1000 x 2000mm, 1219 x 2438mm ( 4ft x 8ft ), 1219 x 3048mm ( 4ft x 10ft ), 1500 x 3000mm, other customized |

Surface finish | Cross Hairline |

Titanium Coating Colors | Ti-gold, Champagne gold, Rose gold, Rose red, Wine red, Coffee, Pink, LIC Ti-black, PVD coating Ti-black, Jewelry blue, Emerald green, Violet, Red copper etc. |

Certificate | SGS ROHS, SGS Abrasion Resistance, SGS Adhesion Test of Coating, SGS Natural Salt Spray Test |

CONTACT US

> Email: info@topsonstainless.com

> Address: C1-2,Building C,No.3,Xinglong Road 11,Guanglong Industrial Zone,Shizhou Community, Chencun Town, Shunde, Foshan City, Guangdong, China